Methods of reduction of concentration of the particulate pollutants in industrial gases

These lectures are devoted to processes and equipment used for the removal of particulate pollutants and of gaseous pollutants. Particulate pollutants may be solid particles – dust – and liquid particles – drops. Dust removal processes and equipment depend primarily on the physical properties of the dust like diameter distribution and density while the chemical properties are less important. On the other hand, for gaseous pollutants it is the chemical properties that will decide on the process and equipment applied for its removal.

To reduction of concentration of the suspended particles in gases the devices of preliminary (rough) clearing are applied. These devices are differed a simplicity, reliability in operation and did not demand of the big power expenses.

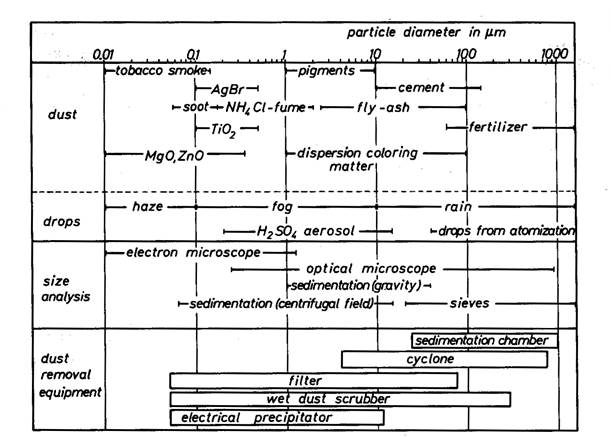

Fig. 2.1 – Typical particulate materials, size analysis procedures, and equipment

On a way of action the devices of preliminary clearing of gases can be divided into the following groups:

1) Devices, which principle of action is based on use of gravitational forces, - chambers of dust precipitation;

2) Devices in which force of inertia is used, - inertia-type dedusters;

3) Devices, which principle of action is based on use of centrifugal forces, - cyclones;

4) Devices of wet type – hollow scrubbers, Venturi scrubbers and other.

Cyclones and wet dedusters in practice of gas purification are applied and as devices of preliminary clearing gases, and as devices of independent clearing. Thus, they occupy intermediate position between devices of rough and thin clearing of gases.

So, the dust removal equipment available may be divided into two large groups: dry dust removal equipment and wet dust removal equipment. In dry dust removal equipment dust separation from the carrier gas is achieved directly, i.e. in the dry state, without the use of a special dust collection agent like water drops. The collected dry dust can be directly disposed of. The use of dry dust removal equipment involves however the danger of dust explosion. Therefore, special measures have to be taken to prevent dust explosion and pressure release in case of explosion.

Дата добавления: 2017-11-04; просмотров: 610;