Chambers of dust precipitation (gravitational chambers).

The basis of action of chambers of dust precipitation is gravitational sedimentation of dust particles.

Gravitational sedimentation or sedimentation by action of gravity represents the simplest method of sedimentation of dust. Time of passage by gases of chamber makes:

t = V / Vg = L· Bc · H / V,

where V - volume of the chamber, m3;

Vg - the volumetric charge of gases, m3/s;

L – length of the chamber, m;

B – width of the chamber, m;

H – height of the chamber, m.

For same time by gravity the particle will pass a way h

h = wm · τ

where wm - average speed of a particle, km/s.

Fractional efficiency of chambers of dust precipitation is determined by the relation h/Н. If value h is more or equally Н, all particles of this size and larger are caught by the chamber. At designing chambers it is necessary to take into account an opportunity of secondary dust ablation also. It is necessary, that speed of a gas stream was not higher than 3 km/s.

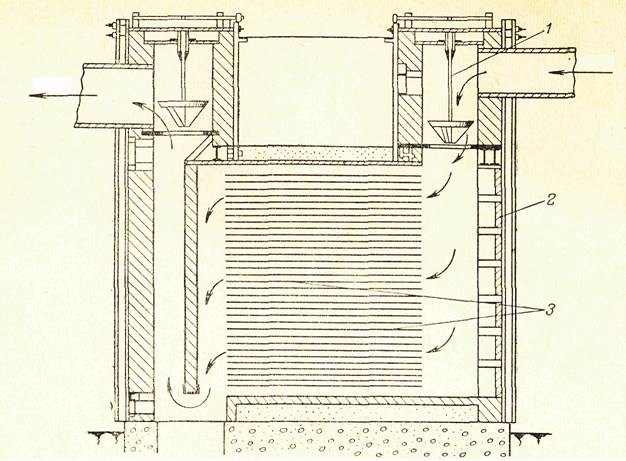

In figure 2.2 the design distributed in the industry chamber of dust precipitation is shown. The small height between the shelfs through which passes a dusty gas stream, causes the effective catching of dust. In this case the particle for sedimentation must pass a way equal Н/N (where N – number of sections in the chamber). Fractional efficiency of the chamber of such type makes up hN/Н.

Lack of the chamber, shown in figure 2.2, consists in difficulty of clearing of a settled dust.

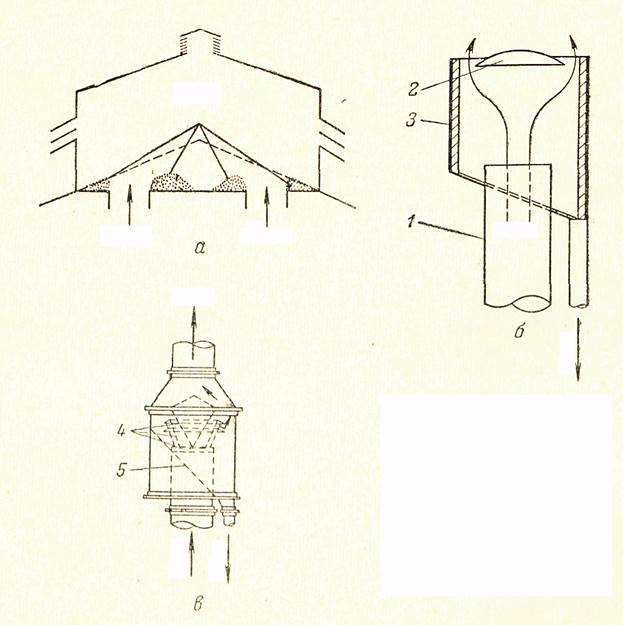

Chambers of sedimentation are used for sedimentation of a dust from vertical gas streams too. In this case the particles which speed of sedimentation is higher than speed of a gas stream are settled. Devices for dust sedimentation from an ascending vertical gas stream are shown in figure 2.3. The device, shown in figure 2.3а, allows to direct a part of a dust back; the unloading of a settled dust is made periodically during a stop. In chambers (2.3б, 2.3в) the dust is removed continuously.

Fig. 2.2 – Multiply section dust-collecting chamber

The basic advantages:

1) Simplicity of a design;

2) Low cost;

3) Small power consumptions;

4) An opportunity of catching of an abrasive dust;

5) An opportunity of catching of a dust in a dry kind;

6) Work of the chamber did not depend at temperature.

Lacks: very bulky chambers are necessary for achievement of high efficiency.

Efficiency of catching of fine dispersed dust with particles less than 5 microns equal zero even in chambers of very big sizes, large particles of a dust in the size 30-40 microns and more are caught well.

Fig. 2.3 – Vertical dust-collecting chamber: a – without dust removal; б, в – with dust removal; 1 – gas conduit; 2 – reflecting disk; 3 – refractory coating; 4 – reflecting cones; 5 – sloping plate.

Дата добавления: 2017-11-04; просмотров: 833;