Absorption installations

Absorption is the process by which a gas is dissolved in a liquid. In most cases absorption is the process of selective removal of a component from a gas mixture. The gas mixture consists of insoluble and soluble components. The soluble component is called the solute; it is transferred from the gas mixture to the liquid. The liquid consists of the solvent and the absorbate. Sometimes, the liquid mixture including the absorbate is called the absorbent. Absorption is one of the most advanced techniques applied to the separation of gas mixtures. It is widely used in industry; in the areas of air pollution control it has become one of the important processes for the abatement of gaseous pollutants.

Counter-flow contact gas - liquid can be carried out by the next ways:

1) Bubbling of gas through capacity with an absorbing liquid. The capacity is usually supplied with a tube with apertures, so-called porous gas distributor, through which passes gas. The degree of dispersion of gas can be increased by hashing of a liquid.

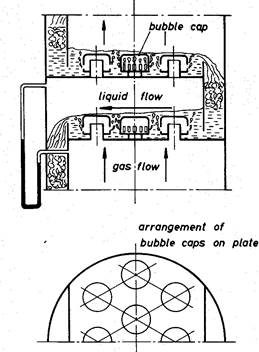

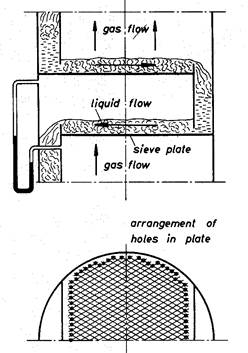

2) Passing of gas through bubble plates in the plate type column. Plate type columns are more expensive, than packed columns, but they allow work with very great volumes of a liquid.

3) Passing of gas through usual packed column. It isthe most widespread installation.

4) In irrigating towers which are widely used for removal of firm particles.

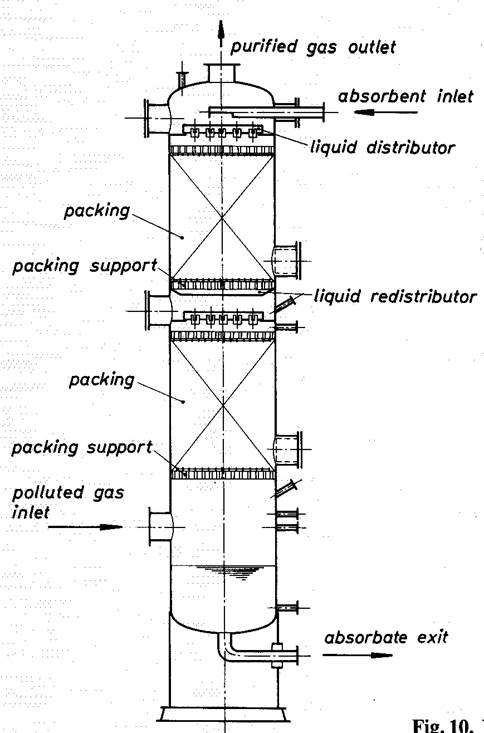

The design of packed columns is very simple. Packed elements are loaded into them or randomly, or stacked in the certain order. The packing is located above an entrance aperture for gas, the liquid flows down along packing. As packing fragments of rocky breeds and stones are applied, it can have the form of rings, saddles, grids. Packing rings can be metal, glass, ceramic or plastic depending on corrosion aggression of environment in the tower. It is necessary carefully to distribute a liquid that it moistened all packing, it is especially important for the top part. The basic lattice should be mechanically strong to sustain weight of the packing and the liquid if the liquid fills the column in case of flooding. To avoid flooding, the structure of lattice should be more "open", than structure of packing.

The general lay-out of an absorption plant includes the following stages. An absorption plant consists of the absorption unit proper, the regeneration unit and all necessary auxiliary equipment and machinery. The gas mixture with the gaseous pollutant, namely, the solute or absorptive, enters the absorption unit at the bottom. Within the absorption unit the gas mixture is brought into contact with the liquid, called the solvent or absorbent. During the time of contact the pollutants is at least partly transferred to the liquid. The purified gas mixture leaves the absorption unit at the top. The liquid that normally enters the absorption unit at the top, leaves the unit at the bottom, carrying with it the pollutant, and from there is directed to the regeneration unit. Here, the absorbent is treated in such a way that the absorbent may be recycled and the pollutant disposed of appropriately.

Regeneration may be achieved by various processes such as vaporization, rectification, steam stripping, desorption, extraction etc. If necessary, a regenerative medium is introduced to extract the pollutant. In most cases, energy and mass transfer considerations will lead to the installation of heat exchangers in the solvent regeneration cycle. Because of increasing solubility with increasing of temperature and decreasing of pressure, the absorption process should be carried out at relatively low temperature and high pressure. In air pollution control however, the polluted gases are in the most cases available at higher temperatures and low pressure. Therefore, the waste gas has to pass through a precooler in order to reduce the temperature. On reducing the temperature by about 15 0 C, the vapor pressure for many pollutants is reduced to 50 % as is the minimum flow rate of the liquid absorbent. Thus, in air pollution control technology the absorption process has to be applied under very unfavorable conditions. This is the reason why all possibilities for the improvement of the absorption process have to be used. This requires an understanding of the physical and chemical details of the process in order to improve the existing equipment and to develop more efficient equipment.

Fig. 2.21 – Design of a two-stage packed column

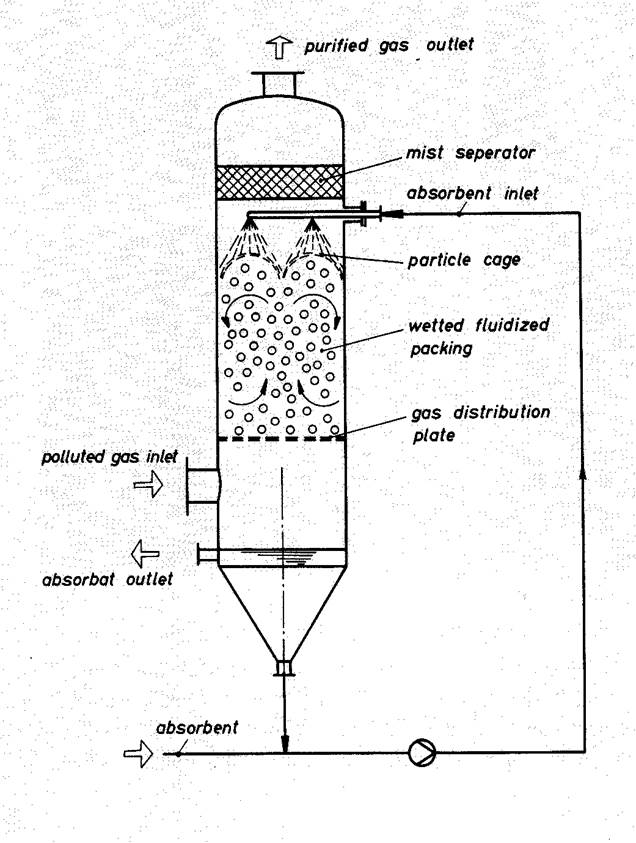

Fig. 2. 22 – Design of a one-stage fluidized packing column

Fig.2. 23 –Design of column with bubble cap plates

Fig.2. 23 –Design of column with bubble cap plates

|  Fig. 2. 24 – Design of column with sieve plates

Fig. 2. 24 – Design of column with sieve plates

|

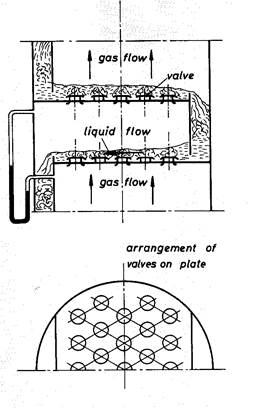

Fig. 2. 25 – Design of column with valve plates

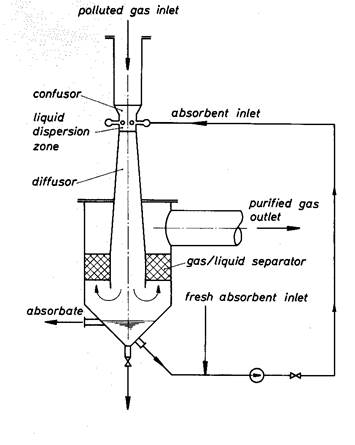

Fig. 2. 26 – Design of a Venturi column

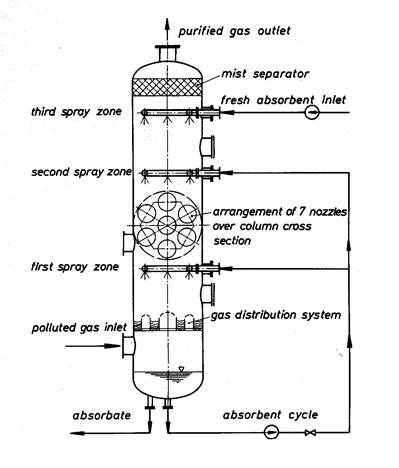

Fig. 2. 27 – Design of a nozzle spray column

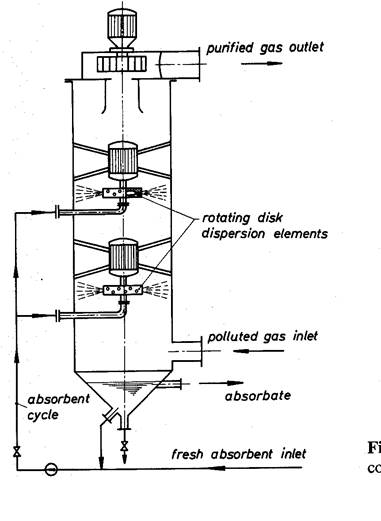

Fig. 2. 28 – Design of a rotating disk spray column

Дата добавления: 2017-11-04; просмотров: 1038;