Think of different building materials and answer the following questions

1. When do we use the term “metal bridges”?

2. What advantages does steel offer in comparison with timber or reinforced concrete?

3. What is low alloy steel?

4. What joining methods for metal elements do you know?

8.2 Read the text and check your answers. How much did you guess correctly?

Engineers design metal bridges using cast iron, iron, steel and aluminum alloys. Cast iron is an alloy of iron that contains carbon, along with varying amounts of silicon and manganese. Cast iron is hard and brittle owing to its high carbon content and therefore is inferior to wrought iron for most purposes. Wrought iron is soft and ductile. Cast iron is strong in compression but weak in tension. Wrought iron, on the other hand, is as strong in compression as cast iron, but it has much higher tensile strength.

| |

| a - The earliest cast-iron bridge across the River Severn in Great Britain | b - Steel Bridge with Long Middle Superstructure Spans |

Figure 8.1 Metal Bridges

The Iron Bridge, spanning the River Severn near Coalbrookdale in Great Britain, is the first cast iron structure (fig. 8.1a), built in 1779 with semicircular arch spans. Each span was 30.6 m long, and has five haunch ribs.Abraham Darby designed the Iron Bridge after French engineers had cast a similar bridge a few years earlier, but they never completed their structure. Though the pedestrian Iron Bridge isa British national monument, it is still used.

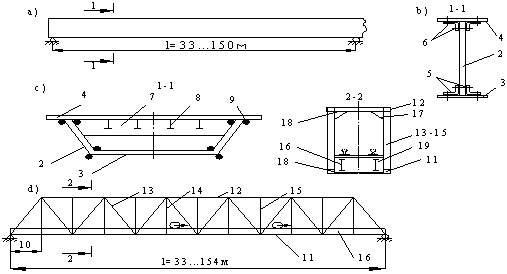

Figure 8.2 Diagram of Metal Bridge (схема металлического моста)

a – Metal Girder (металлическая балка);

b – Riveted Superstructure (клёпаное пролётное строение);

c – Welded Superstructure (сварное пролётное строение);

d - Trussed Girder (сквозная ферма).

1 – Girder (балка); 2 – Web (стенка, ребро балки); 3 – Lower Chord (нижний пояс);

4 – Top Chord (верхний пояс); 5 – Angle Ties (уголки);

6 – Rivets (заклёпки); 7 – Cross Beam (поперечная балка);

8 – Longitudinal Ribs (продольные ребра); 9 – Weld Seam (сварной шов);

10 – Panel Length (длина панели моста); 11 – Bottom Chord of Truss (нижний пояс фермы);

12 – Top Chord of Truss (верхний пояс фермы); 13 – Diagonal Strut (раскос);

14 – Hanger (подвеска); 15 – Tie (стойка); 16 – Rib (ребро);

17 – Cross Bracing (поперечные связи);

18 – Longitudinal Braces (продольные связи); 19 - Cross Beam (поперечная балка)

In the 19th century, bridge builders used wrought iron and later high-strength steel. It is stronger and superior to iron in both tension and compression. Due to its rigidity and durability, steel is simply the best building material. It allows easy metalworking compared to other building materials.

Low alloy steel offers superior quality owing to the fact that it contains small amount of elements like nickel, chromium, manganese, etc. Currently stainless steel grades are widely used in both space and building industries. Such steel does not need any surface protection because of the chromium oxide film on its surface.

Metal superstructures, which are suited to intermedium and long spans, have made good appearance lengths between 50 and 1,500 m with continuous and discontinuous beams (fig. 8.2a), frames, arches, trusses (fig. 8.2d) cantilever structures, combined systems, etc. The length of the structures is 150 m for discontinuous beams, and 500 m for cantilever-beam spans.

Frame span length is up to 100 m. Bridge engineers employ trusses for spans of 200 m, and for arch spans of 300 m in length.

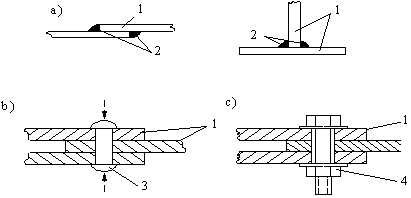

Figure 8.3. Joints of Metal Bridge Components

(соединения элементов металлических мостов)

1 – Component (элемент); 2 – Weld Seam (сварной шов); 3 – Rivet (заклёпка);

4 – High Strength Bolt (высокопрочный болт)

Metal bridges offer the following advantages: high-strength building material; large possible span length; durability; large-scale production of bridge construction elements; constructability, access to maintenance and easy overhaul.

The disadvantages of metal bridges include considerable steel consumption, corrodibility, high dynamic sensitivity, and high maintenance costs (due to the need of painting).

Welding (fig. 8.3a), rivets (fig. 8.3b) or bolts (fig. 8.4c) are effective for joining metal elements used in construction. Welding is the largest costs saving method but it is not as reliable as riveting or bolting. Rivets are not widely used because use of them is rather complicated, whereas bolts are commonly used.

Дата добавления: 2015-01-26; просмотров: 1745;