Single-Phase Induction Motors

Single-phase induction motors enjoy wide application where power demands are low, up to 1 or 2 kW. This type of motor differs from a three-phase counterpart in that it has a single-phase stator winding. The motor comes in the squirrel-cage and wound-rotor types. The crux of the single-phase motor problem is that the motor requires auxiliary means for starting because it cannot develop the starting torque and remains at standstill when connected to the power line.

An external force applied to the motor accelerates the rotor from rest, which then develops the torque. The inability of a single-phase motor to produce the starting torque is its substantial drawback. As noted above, the motor needs an auxiliary device for starting.

The simplest starting device consists of two windings carried on the stator and spaced half the pole pitch apart (90 electrical degrees). These windings draw power from a balanced two-phase network, so that the voltages applied to the windings are equal and 90° out of phase. At such voltages the currents through the windings are also in phase quadrature, which feature coupled with the shift of the windings in space makes it possible to produce the revolving magnetic field and hence, the required starting torque.

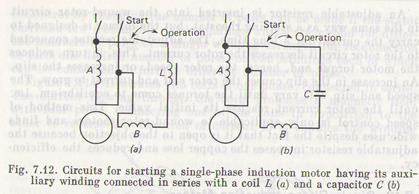

In actual fact, the two-phase network is commonly absent, and the single-phase motor is started by connecting its two windings to the common single-phase line. To provide for the phase shift between the currents in the windings, which is equal to about ±π/2 (one-fourth the period) the main (inducing) winding A is connected directly across the line or through a starting resistor, and the auxiliary (starting) winding В in series with a coil L (Fig. 7.12a) or capacitor С (Fig. 7.12b).

The starting winding is held connected to the supply only during the starting period. At the instant when the rotor is up to speed, this winding is disconnected from the line by a centrifugal switch or

a suitable relay and the motor operates as a single-phase machine. Any three-phase induction motor can be set up for single-phase operation. For this, its main winding consisting of two phases in series is put directly across the single-phase line, and the auxiliary winding (the third phase) indirectly through a starting element such a resistor, coil, or capacitor.

A capacitor (two-phase) motor is a single-phase induction motor with two windings arranged on the stator and a cage winding on the-rotor. The auxiliary winding is designed to carry current for a long time and is left in the circuit during the motor operation. The revolving magnetic field appearing in the capacitor motor in operation improves its performance as against that of an ordinary single-phase motor. An increase in capacitance leads to an increased starting torque of the motor. But this increase in the capacitance at speed is objectionable because the capacitor (capacitor bank) tends to decrease the speed and efficiency of the motor. Capacitor-run motors are made with two capacitor banks, starting and running capacitors, to improve their operating characteristics.

Дата добавления: 2015-06-17; просмотров: 1172;