Motors with Improved Starting Characteristics

As mentioned above, squirrel-cage motors are simple in design and reliable in operation, for which reason they have gained wide acceptance. Unfortunately, they show poor starting characteristics. Some designs, however, are available which employ modified rotors to reduce or avoid this disadvantage. These are double-cage rotors and

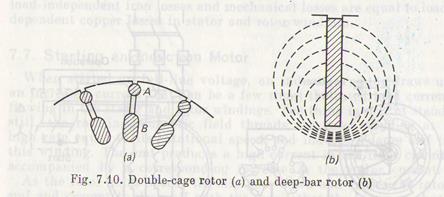

deep-bar rotors. The double-cage rotor, first suggested by I.O.Dolivo-Dobrovolsky in 1889, consists of two cage windings (Fig. 7.10a). The number of slots for the outer winding A can be equal to or different from the number of slots for the inner winding B. The outer winding A is made from bars of small cross section, and the lower winding В from bars of large cross section, so the resistance of A is much higher than that of B, BA >> RB. Since the bars of В are deeply embedded into the rotor body and enclosed by steel, the inductive reactance of В is much greater than that of A, XB >> XA.

The motor operates on the following principle. At the instant of connecting the motor to the supply line, the rotor remains stationary and the rotor frequency is equal to the line frequency, f2=f1. The current in windings A and В distributes itself inversely as the impedances of these windings. Since the reactances of windings in induction machines are much higher than their resistances, the current, at starting, divided between the windings A and В is found to be approximately in inverse proportion to XA and X B. The current thus mainly flows through the bars of outer cage winding A that has a lower inductive reactance and a higher resistance. The winding A is a starting winding.

When the motor carries the rated load, the slip is small and, hence, the rotor frequency is also small, f2≈0. The inductive reactances of the windings are now of no importance and the currents in A and В are inversely proportional to RA and RB In the running conditions, the current thus largely flows through the bars of inner winding В having a lower resistance. The winding В is an inducing winding. This rotor design makes it possible to increase the rotor winding resistance at starting and, hence, to reduce the starting current and to augment the starting torque m the same way as is done with the aid of a starting rheostat-

In a deep-bar rotor motor, the cage winding is built of thin and high strips, or bars (Fig. 7.10b). In such a rotor design, the current is forced toward the upper part of the bar because the lower part is linked with a larger leakage flux than the upper part.

The effect of displacing the current toward the upper portions of bars shows up most strongly at the instant of starting the motor, when the rotor frequency is equal to the power line frequency. Consequently, this effect affords an increase in the resistance of the rotor winding with the attendant increase in the starting torque. As the rotor continues to accelerate, the rotor frequency gradually decreases and the current spreads more uniformly over the cross section of bars. At the rated speed, the current distribution over the bar cross section is almost uniform.

The starting torque developed by these types of motor is Ts = (1.0 to 1.5) Tr and the starting current is Is = (4 to 5)Ir, where Tr is the rated full-load torque and Ir is the rated full-load current.

Thus, double-cage rotor motors and deep-bar rotor motors have higher starting torques and lower starting currents than ordinary squirrel-cage motors. But the former are somewhat inferior to the latter in performance characteristics such as cosφ, efficiency, and breakdown torque due to a higher leakage flux, i.e. higher inductive reactance of rotor windings.

Дата добавления: 2015-06-17; просмотров: 1231;