Principle of Action and Construction

The action of transformers depends on the principle of electromagnetic induction. If the transformer primary connected to an ac circuit of the power source carries an alternating current, the varying magnetic flux set up by the current in the transformer core links the turns of the secondary and induces an emf in the secondary. The emf forces the current to flow in the secondary circuit connected to loads. So, electromagnetic induction enables the transformer to transfer energy from the primary to the secondary circuit, but at the other voltage that is suitable for the loads supplied from the secondary circuit.

The steel core of a transformer provides a magnetic circuit for the primary and the secondary and thus improves the magnetic coupling between them. To reduce eddy-current losses, transformer cores are made up of an assembly of thin steel laminations 0.50 and 0.35 mm thick, coated with a heat-resistant insulating vanish. Transformer steel used for cores comes in the cold-rolled and hot-rolled types.

In distinction from hot-rolled steel, cold-rolled steel has a higher permeability in the direction of rolling and a relatively low permeability transverse to the rolling direction. Cold-rolled steel laminations of a core are stacked up so that the flux path is parallel to the direction of steel rolling. The core of a small-power transformer usually comprises a cold-rolled steel strip.

In high-power transformers, the cores consist of steel laminations. Cold-rolled steel is cut into strips so that the magnetic flux in the assembled core is in the direction of rolling. Hot-rolled steel is isotropic, i.e. exhibits the same permeability in all directions. The cores for low-power transformers are built up of Ш- or П-shaped laminations punched from hot-rolled sheet steel.

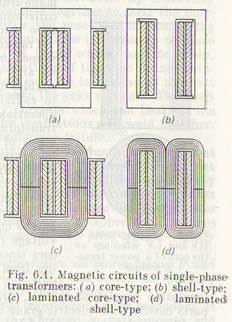

Depending on the form of the core used and arrangement of windings on it, transformers fall into two groups, core type and shell type. The magnetic circuit of a core-type single-phase transformer is in the form of a single ring which consists of two legs surrounded with windings and two yokes at the top and bottom, so the magnetic flux closes on itself entirely along the steel path (Fig. 6.1a). The magnetic circuit of a single-phase shell-type transformer consists of the core such as illustrated in Fig. 6.1b. The windings entirely encircle one leg of the core and the two extreme legs (yokes) surround the windings, thus partially protecting them from mechanical damage.

Depending on the form of the core used and arrangement of windings on it, transformers fall into two groups, core type and shell type. The magnetic circuit of a core-type single-phase transformer is in the form of a single ring which consists of two legs surrounded with windings and two yokes at the top and bottom, so the magnetic flux closes on itself entirely along the steel path (Fig. 6.1a). The magnetic circuit of a single-phase shell-type transformer consists of the core such as illustrated in Fig. 6.1b. The windings entirely encircle one leg of the core and the two extreme legs (yokes) surround the windings, thus partially protecting them from mechanical damage.

Both core-type magnetic circuits (Fig. 6.1c) and shell-type magnetic circuits (Fig. 6.1 d) are made from cold-rolled steel laminations.

High-power transformers produced today are essentially of the core type since they require a simpler insulation of the high-voltage winding from the core than is the case for the shell-type counterparts. In low-power transformers the winding voltages are low, so-the insulation problem does not present difficulties. These transformers often come in the shell-form design, which has one set of low-voltage and high-voltage coils, whereas the core-form design calls for two sets of coils.

In the shell-type core, the magnetic flux that leaves the coil-carrying leg divides into two equal parts, so one of its parts closing-through one of the free legs is half that through the coil-carrying-leg. For this reason, each of the interlinked free legs has half the cross section of the coil-carrying leg.

Instrument and laboratory transformers and also radio-frequency transformers often employ toroidal (ring-shaped) cores noted for a relatively low reluctance and extremely small magnetic flux leakage. With the coils uniformly distributed over the ring of the toroid, the transformer becomes insensitive to external magnetic fields irrespective of their direction. Toroidal magnetic cores are made from cold-rolled steel strip, with the coils wound on the cores on special shuttle-type machines.

Transformer windings are preferably shaped into cylindrical (round) coils concentrically wound on the core. Such a shape enables the cores to stand up more strongly to radial mechanical forces arising during operation of the transformer. In some cases, transformers use rectangular, oval, and other forms of coils. The coils intended to carry low currents are wound with turns of copper or aluminum round wire. The coils designed for large currents are wound from strips of rectangular cross section.

Transformer windings are preferably shaped into cylindrical (round) coils concentrically wound on the core. Such a shape enables the cores to stand up more strongly to radial mechanical forces arising during operation of the transformer. In some cases, transformers use rectangular, oval, and other forms of coils. The coils intended to carry low currents are wound with turns of copper or aluminum round wire. The coils designed for large currents are wound from strips of rectangular cross section.

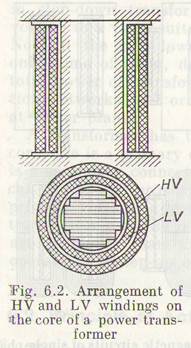

The arrangement of cylindrical windings on the core is shown in Fig. 6.2. The low-voltage (LV) winding is placed next to the core since it is easier to insulate the LV winding from the magnetic iron than the high-voltage (HV) winding. The LV coil-to-iron insulation consists of spacers, strips, washers, and other insulating parts mostly from electric-grade cardboard. The HV winding must also be insulated from the LV winding.

When using cylindrical coils, it is desirable that the magnetic «ore should be round in cross section, since in this case the coil fully encircles the core without voids. The smaller the area of voids, the shorter the length of the turns. This effects savings in the mass of wire at the given cross section of the core. But it is impracticable to fabricate a round core because its assembly would necessitate a large number of steel sheets of various widths. For this reason, the core of a high-power transformer has a step-like cross section with not more than 9 or 10 steps. The number of steps results from the number of angles in one-fourth of the circle. Fig. 6.2 illustrates the three steps in the cross section of the magnetic core.

To enable a better removal of heat from a high-power transformer, the cores (and the windings too) are made complete with cooling vents in the planes parallel and perpendicular to the planes of steel laminations.

In low-power transformers, the cores used are rectangular in cross result that its dielectric strength decreases. To ensure the trouble-free operation of a transformer, it is necessary to control the temperature of oil, timely replace the contaminated oil, and periodic-- ally dry and clean it. Variations in the temperature of a transformer lead to changes in the level of oil in the tank. To keep a transformer always immersed in oil, the transformer tank is equipped with an oil conservator (expansion tank). The oil conservator is a steel drum mounted on the tank cover and connected with the tank through a tube. The oil level changes only in the conservator, which reduces the oil surface in contact with air and guards the oil against pollution and moisture.

Дата добавления: 2015-06-17; просмотров: 1198;