Engines

The specified power plant for the A‑12 was two Pratt & Whitney JT11D20 A engines (designated J58 by the US military). Known as JJ engines, each developed 32,500lb of thrust (as both the YF‑12 and SR‑71 designs were heavier than the A‑12, their modified YJ engines produced 34,000lb of thrust). This high bypass ratio afterburning engine was the result of two earlier, ill‑fated programs: Project Suntan together with Pratt & Whitney’s JT9 engine that lost out to General Electric’s J93 to power the North American XB‑70 Valkyrie. So Pratt & Whitney then reduced the engine’s size by 20 percent and offered it under the J58 designator for the Vought F8U‑3, which in turn lost out in competition against McDonnell’s F4H‑1.

Article 133 (60‑6939) was the final A‑12 off the line. Note how both outboard wing sections hinge upward to allow installation of and access to the J58 engines; and the Q Bay behind the cockpit that provided the pressurized compartment within which the camera was installed. (Lockheed Martin)

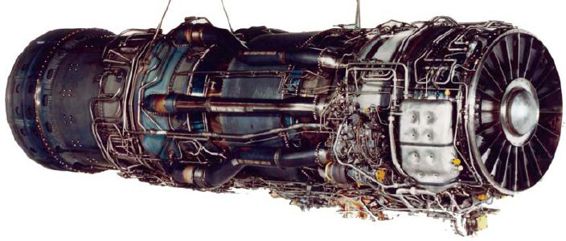

The Pratt & Whitney J58 continued to be developed throughout its life, eventually generating 34,000lb of sustained thrust whilst cruising in afterburner. Three of the six unique compressor bypass tubes can clearly be seen. (Pratt & Whitney)

Although relatively conventional, the original single‑spool high pressure ratio turbojet was rated at 26,000lb in afterburner and had already completed 700 hours of full‑scale engine testing, with results being very encouraging. As testing continued, however, it became apparent that due to the incredibly hostile thermal conditions of sustained Mach 3.2 flight, only the basic airflow size (400lb per second of airflow) and the compressor and turbine aerodynamics of the original Navy J58 P2 engine could be retained (and even these were later modified). The stretched design criteria, associated with high Mach number and its related large airflow turn‑down ratio, led to the development of a variable cycle (later known as a bleed bypass) engine; a concept conceived by Pratt & Whitney’s Robert Abernathy. This eliminated many airflow problems through the engine by bleeding air from the fourth stage of the nine‑stage, single‑spool axial‑flow 8.8:1 pressure ratio compressor and channeling this excess air through six low compression ratio bypass ducts. It was then reintroduced into the turbine exhaust, near the front of the afterburner, at the same static pressure as the main flow; this reduced exhaust gas temperature (EGT) and produced almost as much thrust per pound of air as the main flow, which had passed through the rear compressor, the burner section, and the turbine. Scheduling of the bypass bleed was achieved by the main fuel control as a function of compressor inlet temperature (CIT) and engine rpm. Bleed air injection occurred at a CIT of between 85 and 115 degrees C (approximately Mach 1.9).

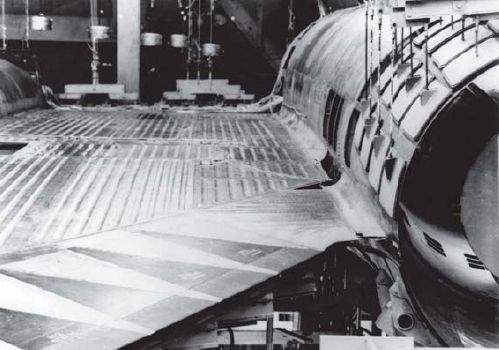

Undergoing stress testing, note the wedges of dielectric material installed into the serrated wing leading edge to reduce the aircraft’s RCS. Note also the chordwise corrugations pressed into the inboard section of the wing to minimize the effects of thermodynamic expansion. (Lockheed Martin)

The successful execution of Oxcart’s mission depended upon the air refueling support supplied by specially modified USAF KC‑135Q tankers flown by the 903rd Air Refueling Squadron, based at Beale AFB, California. (Lockheed Martin)

Дата добавления: 2015-05-08; просмотров: 1671;