A thermal thicket

The innovative use of shape and materials to produce as stealthy a vehicle as possible was equaled by the necessary use of exotic materials and manufacturing techniques. The best frontline fighter aircraft of the day were the early Century‑series jets, like the North American F‑100 Super Sabre and McDonnell F‑101 Voodoo. In a single bound, the A‑12 would operate at sustained speeds and altitudes treble and double respectively those of such contemporary fighters. The technical challenge facing the Skunk Works team was vast and the contracted timescale in which to solve them was incredibly tight. Johnson would later remark that virtually everything on the aircraft had to be invented from scratch.

Operating above 80,000ft, the ambient air temperature was often below ‑60 degrees C and the atmospheric air pressure just 0.4 pounds per square inch; but cruising in afterburner at a speed of a mile every two seconds, airframe temperatures soared from between 245 and 565 degrees C. However, during the subsonic air refueling phase of a mission, the airframe would be subjected to steady‑state temperatures of ‑65 degrees C. Thermodynamic considerations therefore were fundamental.

Sustained operation in such an extreme temperature environment meant lavish use of advanced titanium alloys, which accounted for 85 percent of the aircraft’s structural weight; the remaining 15 percent was comprised of composite materials. The decision to use such materials was based upon titanium’s ability to withstand high operating temperatures; it also weighs half as much as stainless steel but has the same tensile strength – high‑strength composites were not available in the early 1960s. The particular titanium used was Beta‑120/Ti‑13V‑11Cr‑3A1, which can be hardened to strengths of up to 200 Ksi. But using this advanced material wasn’t without problems – titanium is not compatible with chlorine, fluorine or cadmium. For example, a line drawn on sheet titanium with a Pentel pen will eat a hole through it in about 12 hours – so all Pentel pens were recalled from the shop floor. Early spot‑welded panels produced during the summer had a habit of failing, while those built in the winter lasted indefinitely. Diligent detective work discovered that to prevent the formation of algae in the summer, the Burbank water supply was heavily chlorinated. Subsequently, the Skunk Works washed all titanium parts in distilled water. As thermodynamic tests got underway, bolt heads began dropping from installations; this, it was discovered, was caused by tiny cadmium deposits, left after cadmium‑plated spanners had been used to apply torque. As the bolts were heated to temperatures in excess of 320 degrees C, their heads simply dropped off. The remedy: all cadmium‑plated tools were removed from toolboxes.

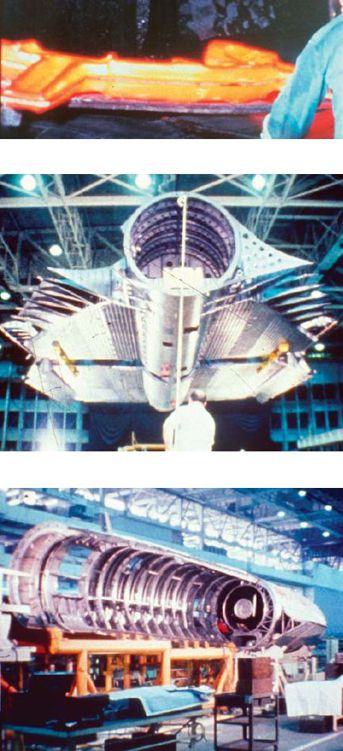

This sequence of three images was taken from a once‑lost cine tape. The first shows a solid titanium ingot being pressed into an engine nacelle ring. The nacelle was an integral part of the wing, acting as a chordwise beam and torque tube, transmitting aerodynamic loads from the outer wing section forwards and redistributing them to the forward and aft wing boxes. The inboard wing sections were in forward and aft box sections, separated by a 3ft 3in‑wide compartment that provided support for the main undercarriage. Finally the inboard section of the right engine nacelle is depicted – the rear of the intake spike mount is already in position. (Lockheed Martin)

One test undertaken studied thermal effects on sheets of large titanium wing panels. When a 4ft×6ft element was heated to the computed heat flux expected in flight, it resulted in the sample warping into a totally unacceptable shape. This problem was resolved by manufacturing chordwise corrugations into the wing outer skins. At the design heat rate, the corrugations merely deepened by a few thousandths of an inch and on cooling returned to their original shape. Johnson recalled he was accused of “…trying to make a 1932 Ford Tri‑motor go Mach 3,” but added that “…the concept worked fine.” To prevent this thin titanium outer skin from tearing due to differential expansion rates when secured to heavier sub‑structures, the Skunk Works developed standoff clips; these provided structural continuity while creating a heat shield between the adjacent components.

Дата добавления: 2015-05-08; просмотров: 1176;