Read the text to get a clear idea of building materials and construction technologies for piers and foundations. Go down the word list and take note of professional terminology.

Bridge engineers design and calculate their structures so that the bridge can safely withstand the dead weight; the live load produced by vehicles moving across the bridge; changes in temperature, precipitation, and winds; and, finally, environmental factors including sudden gusts of wind and earthquakes known as the dynamic load.

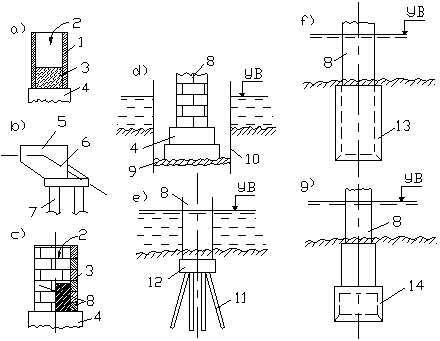

Figure 13.1 Diagram of Piers and Foundations (cхема опор и фундаментов)

a – Cast-in-situ Pier (монолитная опора); b – Precast Pier (сборная опора);

c – Composite Pier (сборно-монолитная опора); d – Foundation on Natural Bed (фундамент на естественном основании); e – Piled Foundation (свайный фундамент);

f – Coffer (опускной колодец); g - Caisson Foundation (кессонный фундамент)

1 – Casing (опалубка); 2 – Concrete Feeding (подача бетона);

3 – Poured Concrete (уложенный бетон); 4 – Footing;

5 – Abutment Blocks (блоки устоя); 6 - Footing; 7 – Pile (свая);

8 – Composite Pier (сборно-монолитная опора);

9 – Concrete Grouting Layer (тампонажный слой бетона);

10 – Sheet Piling (шпунтовое ограждение); 11 – Pile Foundation (свайный фундамент);

12 – Grillage (ростверк); 13 – Coffer (опускной колодец); 14 – Caisson (кессон)

In most cases, bridge piers are made of concrete and/or reinforced concrete. Steel piers may support flyovers and trestle bridges but not frequently.

The classification of concrete piers includes three groups according to construction technology:

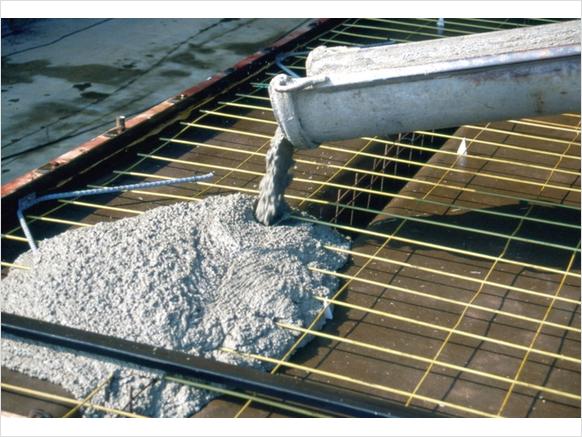

1. Cast-in-situpiers (fig. 13.1a; 13.2). The concrete is placed against the casing in situ. The casing determines the pier shapes and dimensions.

2. Precast piers (fig. 13.1b). The piers are made of prefabricated concrete blocks.

3. Composite piers (fig. 13.1c). These piers, built from the precast concrete units and in situ concrete, are used on a large scale.

|

|

| a – Adaptable Falsework for Pier Geometry | b – Falsework used to support a structure during the construction of piers |

|

|

| c - Concrete is being conveyed into the casing in situ | d – Falsework and cast formwork for placing concrete built on precast concrete segments (Подмости и опалубка для бетонирования, установленные на сборных блоках) |

Figure 13.2 Technologies of Bridge Pier Construction using adaptable casing and falsework

Bridge builders construct concrete arches in situ using temporary supporting casing. After the construction of abutments and piers, they provide a metal or wooden arch falsework, which holds the poured concrete, and later the workers remove it. For steel arches, they employ a cantilevering method. Each side of an arch is built out toward the other, supported by temporary cables until the ends meet. At this point, the arch becomes self-supporting, and the workers remove the cables or arch falsework.

To build foundations for bridge piers in a river, workers need a water-free environment for excavating trenches. They sink caissons filled with compressed air into the riverbed and work inside them. Caissons are large hollow timber, steel or concrete watertight boxes or cylinders with sharp bottom edges. When these structures reach the river bottom, the workers dig out sand and other bottom silt until they come to bedrock. The caissons, moving downward during the digging, finally rest on bedrock, and the workers fill them with concrete. Having poured concrete into the caissons the workers can build the lowest section of piers. In case of suspension bridges, towers are built atop the caissons.

|

|

| a - Construction of Pier Footing | b - Precast concrete pier boxes for footings (Опалубка из сборных блоков для сооружения фундамента опоры) |

Дата добавления: 2015-01-26; просмотров: 1752;