Hydrajet technologies and equipment for production enhancement

The demand for sidetracking exceeds the supply almost twofold even with strong tax burden on the oil and gas production industry.

So the interest of the leading world service companies in development and implementation of hydrajet equipment for production enhancement by drilling laterals or fracturing and improved perforation is understandable. This is an obvious trend for the last few years, and it caused by the opportunity to significantly lower the expenses at implementation of hydrajet technologies with obtaining comparable results as with sidetracking by CT or conventional equipment in some cases.

Packers were used for isolation of most promising intervals and were activated by hydrocarbons present in the oil-based mud in the annulus. Than four fracture-stimulation operations were conducted in a non-cemented hole using a unique fracturing technique that incorporated hydrajet perforating with coiled tubing. The main advantages of this new technology are the possibility of multiple stimulation treatments to be performed in series without the CT being removed from the hole, larger stimulation stages and maximum surface-area exposure to the fracture pressure without formation damage caused by cement.

The results of join development – new equipment for hydrajet applications by specialists from Halliburton and ARC Resources – were presented in the report “New Hydrajet Tool Demonstrates Improved Life for Perforating and Fracturing Applications”. One of the main problems of wide application of hydraulic equipment, which authors were aimed to solve, is rapid failures, resulting in the need for time-consuming and costly tripping out and in the hole for jetting tool replacement. This problem has been attempted to tackle during all the time the hudrajet equipment was in use for oil and gas well service by change of materials and redesign but till now it has resulted only in insignificant performance improvement. That is why the authors made a conclusion that a complete overhaul of the design concepts is to be made.

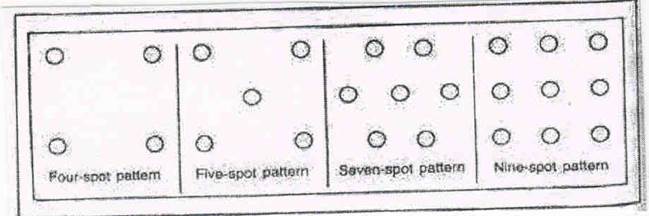

Well Pattern

Some geometric arrangement is usually followed in placing wells. Often, the spacing and arrangement of boundary of wells will determine the position of interior wells, particularly if the property is small. There is more opportunity for scientific well spacing and arrangement when land is held in large tracts rather than small acreages/

In essence, spacing involves drilling preliminary, widely scattered wells at some uniform distance. After this primary system is completed, intermediate wells are drilled between the previous wells at an interval and spacing designed to produce the most economic extraction. This plan has three advantages:

- Initial production is higher than production using plans with usual spacing.

- Production from widely spaced wells is sustained better than closely spaced wells.

The decision on ultimate spacing can be deferred until more information is available. The obvious disadvantage is, of course, the risk of drilling a dry hole. All such risks must be weighed before a decision is made.

The development of an oil property is generally conducted according to one of several plans. A common method is to drill rows of wells across the property from proven territory to unproven territory. This plan gives maximum protection from the entire area beneath the property is productive. It also offers the opportunity to secure vital information on structural and sub-surface conditions for new locations before drilling the next location. A somewhat similar plan is to drill progressively outward from productive lest wells as centers.

In the U.S., the general rule is one well per 40 acres. In Canada, well spacing is somewhat less dense. And in the Middle East, where individual well productivity is high, typical spacing can be as broad as one well per 640 acres. It all depends on the government and its individual regulations.

After the number of wells, the spacing distance, and the pattern are chosen, the wells are drilled. As wells are drilled, they are numbered on each property in the order they are drilled. Large companies sometimes number the wells with reference to their position, regardless of the order of drilling. This can be advantageous because it identifies location immediately: the disadvantage is that you can’t readily tell when the well was drilled.

рис.1

рис.1

Дата добавления: 2015-11-20; просмотров: 1210;