Cameras

Although three different cameras were developed for the Oxcart program, only the Perkin‑Elmer Type I camera was used during operational missions. Equipped with an f/4.0, 18in lens, image frame size was 27.6×6.3in. The unique camera system or “package” utilized two reflecting cube scanners, positioned one behind the other, enabling imagery to be scanned simultaneously onto either the left or right film spool. The forward unit scanned from 21 degrees to the right of vertical, then out to 67 degrees to the left; the aft scanner rotated 21 degrees left from the vertical, then out to 67 degrees to the right – thereby providing 42 degrees of stereo coverage directly below the aircraft, and a total swath 134 degrees wide (which from 80,000ft was 72 miles). The scan cycle time was 4.8 seconds and each frame was timed to produce a 30 percent overlap. Ground resolution was 1ft at nadir (80,000ft vertically below the aircraft) and 3ft, depending upon haze degradation at the outer edges of the image – that’s 36 miles left or right of the Oxcart’s track. Transport of the 5,000ft of film within the camera utilized a concentric supply and take‑up system to ensure that film weight remained centralized, thereby minimizing potential changes in the aircraft’s CG as the film advanced.

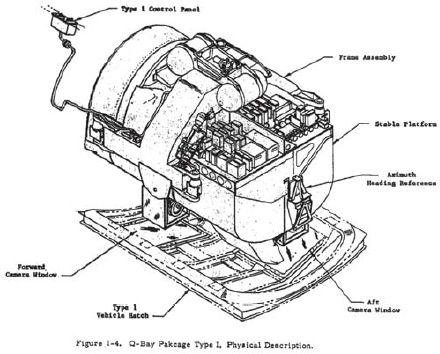

The essence of Project Oxcart was the Type I camera, manufactured by Perkin‑Elmer. The inner works of this very complex camera system remain highly sensitive and even after nearly 50 years, no detailed photographs of the unit have yet emerged. (CIA Pilots Manual)

Because in‑flight temperatures could vary between ‑40 and +290 degrees C, an isothermal window was provided as a protective barrier between such severe temperature gradients and the camera’s film. This window was sealed to the Type I camera and a pump was then used to create a vacuum between the camera base and the glass. The entire camera assembly was lowered through a removable hatch into the Q Bay; the camera lens sought out its targets through the high‑quality quartz window that measured 22in×23in. Problems encountered when bonding the window to its metal frame were eventually overcome during a three‑year, $2 million program, which developed a unique fusing process using high‑frequency sound waves.

Дата добавления: 2015-05-08; просмотров: 965;