Laying of concrete

Laying of concrete in various ways depends on the type of concreted structures. Laying concrete in the formwork should be preceded by validation and the preparatory work. Check mark all the main casing, correctness of its geometrical dimensions. Casing is cleaned of debris, wooden shuttering for about 1 hour before concreting watered, causing release of agents. Check and clean the valves, if they meet the requirements of the project and its specifications are hidden works inspection certificate. Screw-on inserts and anchor detail smeared grease. And only then can you begin to concreting.

The basic technological requirements for the installation of concrete mix are: to provide a monolithic structure and concreted the necessary compaction of concrete mix.

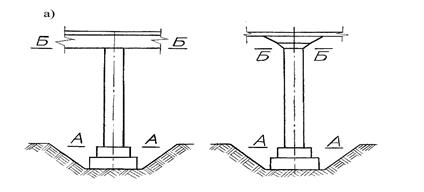

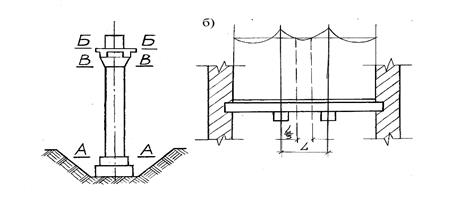

To provide a monolithic reinforced concrete structures is necessary to conduct continuous concreting. However, it is really possible only for small volumes of work. In all other cases, the breaks in concreting are inevitable. In order to joints (joints of hardened concrete and re-stacked) are not found in those places construction, where they threaten its carrying capacity, it is necessary to foresee such joints to provide continuity of concreting in the range between them. Such pre-provided in secure locations seams called sutures workers. The recommended location for construction joints in some designs is shown in pic. 7.11.

In the columns of construction joints are allowed at the top of the foundation, at the bottom of the girders, beams or crane consoles at the bottom of the column capitals beamless the ceilings in frame structures - at the top of haunch between racks and crossbars frames. The booms construction joints are permitted within the middle of the span. When pouring concrete ribbed slabs should be guided by the following: if concreting is in the direction parallel to the secondary beams, the working seam is permitted within the middle third of the span beams, when concreting in the direction parallel to the main beams (joists) - within the middle two quarters of the span of beams and plates. In beamless ceilings make construction joints at mid-span slab. Construction joints in beams and slabs form in a vertical slice.

Construction joints in the vertical elements should be horizontal, the horizontal - vertical. In the presence of sedimentary structures and thermal seams construction joints should be possible to combine them.

Surface hardened construction joints are prepared for installation of concrete mix as follows: purified, purged, knurled, immediately before concreting with cement mortar cover thickness of 20-50 mm.

Sealing of concrete in monolithic constructions carried out mechanically by means of (plugging, vibration, vacuum). At small volumes may hand compaction rammers, skimmers, linings.

The most widespread vibro-compaction because of its versatility, ease of hardware design process. The method is based on the ability of concrete to the thixo-tropic liquefaction under the influence of vibration.

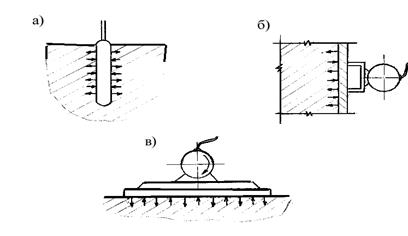

Vibrators come in (deep), exterior (hinged), surface (pic. 7.12).

Pic. 7.11. The recommended location for construction joints:

а – in vertical structures, б – in horizontal structures.

|

Pic. 7.12. Vibrators for compacting concrete:

а – deep, б – mounted, в – surface

Curing

To poured concrete has acquired the required strength at the appointed time, it is necessary for the proper care. Fresh concrete is necessary to maintain moist and prevent it from shaking, no damage, strokes and sudden changes in temperature and fast drying. Lack of care can result in poor quality, defective and unserviceable concrete, and sometimes to the destruction of structures, despite the good quality of materials used, a properly selected concrete mix thoroughly and concreting. Particularly important is the curing during the first days after placement.

Fresh concrete support in the wet state by means of periodic watering and protect from summer sun and winter frost protective coatings. Exposed surfaces of fresh concrete shelter and begin watering, no later than 10-12 hours after concreting, and in hot and windy weather - in 2-3 hours. Nestle well hydrated concrete with canvas, burlap, plastic sheeting and other materials. In dry weather, portland cement concrete to pour water for 7 days, the calcium aluminates cement - at least 3 days, and the plasticized concrete on cement or of plastics - not less than 14 days.

Especially abundant watering is recommended for the night. Watering at temperature of 15 degrees and above is produced in the first three days of not less than every 3 hours and at least once during the night, and in time - at least three times a day. In case of materials for concrete cover is not enough, allowed to replace them through the day with sand or sawdust thickness of 30-50 mm. Laying sawdust on the surface of construction joints are not allowed. In the shelter of concrete sand or sawdust, time interval between watering is increased by about 1.5 times due to the fact that these materials hold moisture better. Poured concrete with water from hoses with connectors, spray jet. To prevent leaching of concrete with water to irrigate begin 5-10 hours after laying. Water used for irrigation, must meet the requirements for water for mixing concrete.

In addition to the open water the horizontal and inclined surfaces of concrete in hot weather, watering and scaffolding. When removing the formwork to columns, walls, beams and other structures continue to pour vertical surfaces of concrete structures prior to the expiration of watering. The best effect in the vertical and steeply inclined watering surfaces is obtained by using a continuous flow of water through the pipes with small holes. In hot, dry climates application of this method is mandatory. Fresh concrete, which is in contact with the flowing groundwater (especially aggressive), must be protected from exposure to them through the temporary diversion of water, isolation devices and other means within three days for the manufacture of aluminous cement and 12 days - for the manufacture of other cements.

Shelter and watering concrete require a considerable amount of work, so large areas (playgrounds, roads, airfield pavements, floors, ceilings, etc.), and the layers allowed torkret instead of shelters and watering special cover painting structures and protective seal (varnish "Etinol "Degteva, bitumen emulsion, diluted bitumen).

The movement of people concreted structures, as well as setting them on forests and formwork allowed not earlier than the concrete reaches strength of 1.5 MPa. Vehicular traffic and concreting machines concreted structures are allowed only by achieving concrete strength provided a project of works.

Дата добавления: 2015-03-07; просмотров: 767;