Preparation of the concrete mix

Preparation of the concrete mix, as a rule, the concrete plants equipped with mechanized and automated units. These plants can be composed of small, medium and large factories reinforced concrete, as well as independent or made in collapsible form and operate directly on the site. These factories, workshops, assemblies, depending on the issue needs a concrete or mortar mix.

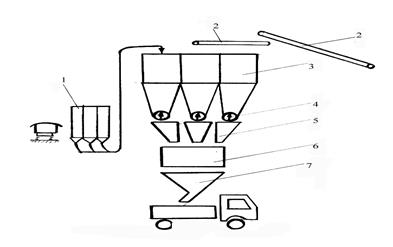

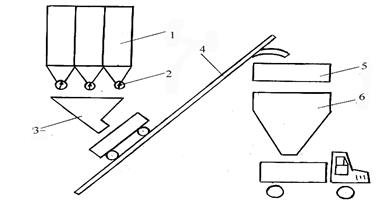

Technological scheme of production of concrete and mortar are single-stage (tall) or two-stage (pic. 7.7 and 7.8).

Pic. 7.7. Single-stage scheme of mixed concrete and mortar:

1 – storage of cement, 2 – conveyor system for feeding inert materials, 3 – feed bin, 4 – dispensers, 5 – hoppers, 6 – mixer, 7 – storage hopper

In addition to such fixed or collapsible concrete solution nodes can be used mobile (cell) concrete solution mounted assembly of heavy vehicle trailers. They usually composed of a two-stage scheme.

The mechanism that determines the quality of concrete, concrete unit performance, the frequency of works is a concrete mixer.

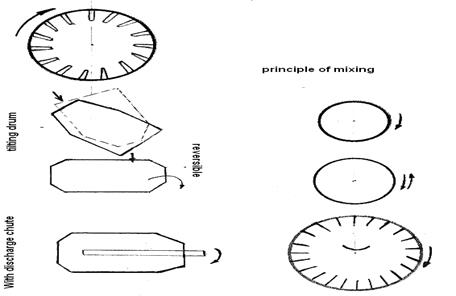

Mixers are (pic. 7.9) gravitational stirring (gravity component) and forced (Pic. 7.10) Gravity - with tilting drum and a discharge chute.

Concrete forced mixing can be divided into cyclic and continuous action.

The most common compulsory mixer – is with rotating bowl used for preparation of hard concrete mixtures.

The duration of cycle in batch mixers:

Тц = tа + tп + tв , (7.1)

where tа, tп, tв – respectively, the duration of loading, unloading and mixing the mixture.

Pic. 7.8. The two-stage scheme of production of concrete and mortar:

1 – feed bin, 2 – dispensers, 3 – hopper, 4 – skip hoist, 5 – mixer, 6 – storage hopper

Дата добавления: 2015-03-07; просмотров: 1033;