Non-mechanical markers

Paint is generally used to mark traffic lanes, spaces in parking lots or special purpose spaces for disabled parking. Colors for these applications vary by locality. Paint is usually applied right after the road has been paved. The road is marked commonly by a truck called a “striper”. These trucks contain hundreds of gallons of paint stored in huge drums. The markings are controlled manually or automatically by the controller.

Paint is generally used to mark traffic lanes, spaces in parking lots or special purpose spaces for disabled parking. Colors for these applications vary by locality. Paint is usually applied right after the road has been paved. The road is marked commonly by a truck called a “striper”. These trucks contain hundreds of gallons of paint stored in huge drums. The markings are controlled manually or automatically by the controller.

Thermoplastic is one of the most common types of road marking. The main advantages of thermoplastic are durability and retro-reflectivity. Most thermoplastic is produced in white and yellow colours.

| http://www.roadtraffic-technology.com/contractors/road_marking/kadcam/ |

Pylons are sometimes used to separate HOV lanes from regular traffic lanes

History of bridges

| http://www.marshruty.ru/Photos/Photo.aspx?PhotoID=b46cc940-65af-4636-8c6a-a555af661142&Size=XL |

cross small wells to get from one place to another. A common form of sticks, logs, and deciduous branches together involved the use of long fibres woven together to form a rope used for binding and holding together the materials used in early bridges.

cross small wells to get from one place to another. A common form of sticks, logs, and deciduous branches together involved the use of long fibres woven together to form a rope used for binding and holding together the materials used in early bridges.

| http://ru.advisor.travel/poi/Arkadiko-Bridge-12306 |

The greatest bridge builders of antiquity were the ancient Romans. The Romans built arch bridges and aqueducts that could stand in conditions that would damage or destroy earlier designs. Some stand today. An example is the Alcántara Bridge, built over the river Tagus, in Spain. The Romans also used cement, which reduced the variation of strength found in natural stone. One type of cement, called pozzolana, consisted of water, lime, sand, and volcanic rock. Brick and mortar bridges were built after the Roman era, as the technology for cement was lost then later rediscovered.

| Alcántara Bridge |

An ancient Indian treatise mentions the construction of dams and bridges. The use of stronger bridges using plaited (переплетенный) bamboo and iron chain was visible in India by about the 4th century. A number of bridges, both for military and commercial purposes, were constructed by the Mughal administration in India.

An ancient Indian treatise mentions the construction of dams and bridges. The use of stronger bridges using plaited (переплетенный) bamboo and iron chain was visible in India by about the 4th century. A number of bridges, both for military and commercial purposes, were constructed by the Mughal administration in India.

Although large Chinese bridges of wooden construction existed at the time of the Warring States (476-221 BC), the oldest surviving stone bridge in China is the Zhaozhou Bridge, built from 595 to 605 AD.

Rope bridges, a simple type of suspension bridge, were used by the Inca civilization in the Andes Mountains of South America, just prior to European colonization in the 16th century.

| http://www.history.ucsb.edu/faculty/marcuse/classes/2c/2c06/lectures/06L03IndRev.htm |

During the 18th century there were many innovations in the design of timber bridges by Hans Ulrich, Johannes Grubenmann, and others. The first book on bridge engineering was written by Hubert Gautier in 1716. A major breakthrough in bridge technology came with the erection of the Iron Bridge in Coalbrookdale, England in 1779. It used cast iron for the first time as arches to cross the river Severn.

During the 18th century there were many innovations in the design of timber bridges by Hans Ulrich, Johannes Grubenmann, and others. The first book on bridge engineering was written by Hubert Gautier in 1716. A major breakthrough in bridge technology came with the erection of the Iron Bridge in Coalbrookdale, England in 1779. It used cast iron for the first time as arches to cross the river Severn.

With the Industrial Revolution in the 19th century, truss systems of wrought iron were developed for larger bridges, but iron did not have the tensile strength to support large loads. With the advent of steel, which has a high tensile strength, much larger bridges were built, many using the ideas of Gustave Eiffel.

In 1927 welding pioneer Stefan Bryła designed the first welded road bridge in the world.

Beam type

The four main factors are used in describing a bridge. By combining these terms one may give a general description of most bridge types:

· span (simple, continuous, cantilever),

· material (stone, concrete, metal, etc.),

· placement of the travel surface in relation to the structure (deck, pony, through),

· form (beam, arch, truss, etc.).

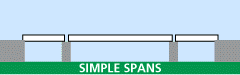

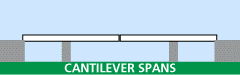

The three basic types of spans are shown below. Any of these spans may be constructed using beams, girders or trusses. Arch bridges are either simple or continuous. A cantilever bridge may also include a suspended span.

|

|

|

|

| http://pghbridges.com/basics.htm |

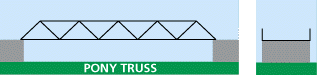

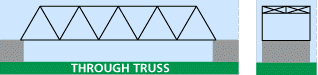

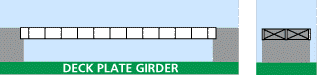

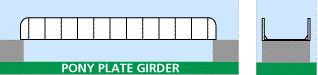

Examples of the three common travel surface configurations are shown in the truss type drawings below. In a deck configuration, traffic travels on top of the main structure; in a pony configuration, traffic travels between parallel superstructures which are not cross-braced at the top; in a through configuration, traffic travels through the superstructure (usually a truss) which is cross-braced above and below the traffic.

|

|

|

| http://pghbridges.com/basics.htm |

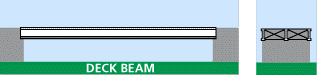

Simple deck beam bridges are usually metal or reinforced concrete. Other beam and girder types are constructed of metal. The end section of the two deck configuration shows the cross-bracing commonly used between beams. The pony end section shows knee braces which prevent deflection where the girders and deck meet.

|

|

| |

| http://pghbridges.com/basics.htm |

| http://pghbridges.com/basics.htm |

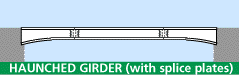

One method of increasing a girder’s load capacity while minimizing its web depth is to add haunches at the supported ends. Usually the center section is a standard shape with parallel flanges; curved ends are riveted using splice plates.

One method of increasing a girder’s load capacity while minimizing its web depth is to add haunches at the supported ends. Usually the center section is a standard shape with parallel flanges; curved ends are riveted using splice plates.

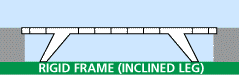

Many modern bridges use new designs developed using computer stress analysis. The rigid frame type has superstructure and substructure which are integrated. Commonly, the legs and deck are a single piece which is riveted to other sections.

|

|

| http://pghbridges.com/basics.htm |

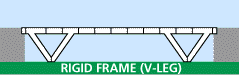

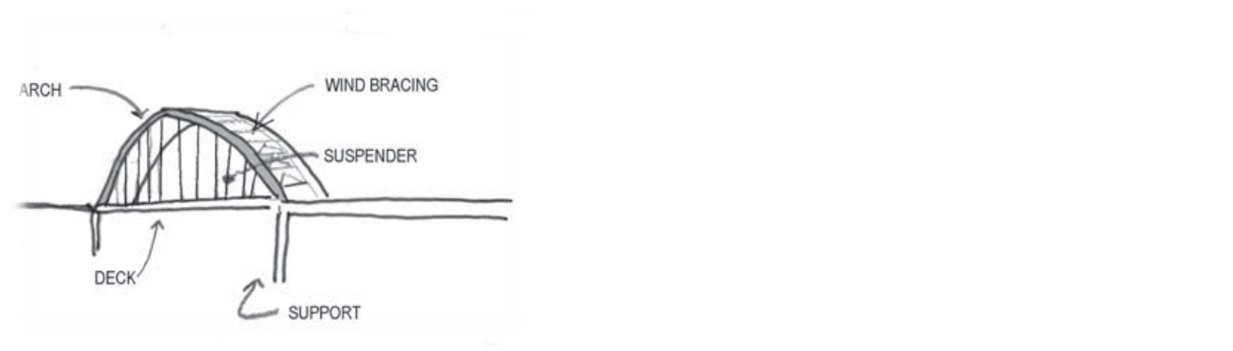

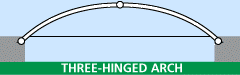

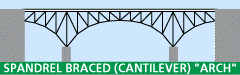

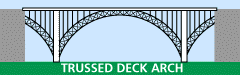

Arch types

Arch bridge is one of the most popular types of bridges, which came into use over 3000 years ago and remained in height of popularity until industrial revolution and invention of advanced materials enabled architect to create other modern bridge designs. However, even today arch bridges remain in use, and with the help of modern materials arches can be build on much larger scales.

The basic principle of arch bridge is its curved design. Abutments carry the load of the bridge and are responsible for holding the arch in the unmoving position.

The basic principle of arch bridge is its curved design. Abutments carry the load of the bridge and are responsible for holding the arch in the unmoving position.

| http://www.aiacincinnati.org/community/abc/ |

|

|

|

|

| http://pghbridges.com/basics.htm |

Arch configuration is another method of classification. Examples of tied arch,trussed arch and spandrel-braced arches are shown. A tied arch is commonly constructed using curved girder sections. A trussed arch has a curved through truss rising above the deck. A spandrel-braced arch carries the deck on top of the arch.

|

|

| |

| http://pghbridges.com/basics.htm |

Arch bridges rely on vertical members to convey the load carried by the arch.

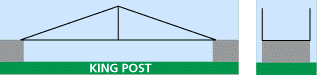

Truss types

Trusses work much like beams: they carry a combination of compression and tension forces. The main difference is that trusses are less heavy than beams. Beams use extra material in some areas; these areas don’t use the full strength available to them. Engineers and builders can determine which portions of beams can be removed. The resulting truss concentrates the forces into many smaller members and eliminates the under-stressed areas of beams.

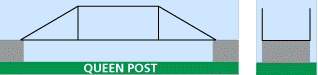

A truss is made of many smaller parts. Once constructed of wooden timbers, and later including iron members, most truss bridges are built of metal. As for the placement of the travel surface in relation to the superstructure truss bridges are divided into king and queen post trusses. The king post consists of two angled supports leaning into a common vertical support. The queen post truss is similar to a king post truss in that the outer supports are angled towards the center of the structure.

|

|

| http://pghbridges.com/basics.htm |

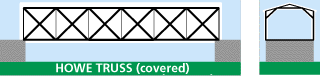

Covered bridges are typically wooden truss structures. The enclosing roof extended the life of the bridge. One of the most common methods used for achieving longer spans was the multiple kingpost truss. A simple, wooden, kingpost truss forms the center and panels are added symmetrically. With the use of iron in bridge construction, the Howe truss in its simplest form appears to be a type of multiple kingpost truss.

|

|

| http://pghbridges.com/basics.htm |

Theodore Burr built a bridge the Hudson River in 1804. This combines an arch with a truss to form a structure both strong and rigid.

|

| http://pghbridges.com/basics.htm |

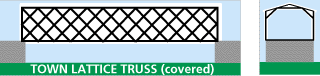

Lattice truss type of bridge uses a number of lightweight elements, easing the task of construction. Truss elements are usually of wood, iron, or steel.

|

| http://pghbridges.com/basics.htm |

Herman Haupt designed his truss configuration in 1839. The Haupt truss concentrates much of its compressive forces through the end panels and onto the abutments.

|

| http://pghbridges.com/basics.htm |

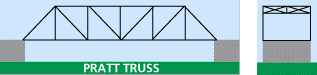

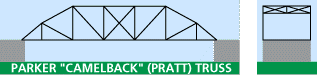

The Pratt truss is a very common type, but has many variations. Originally designed by Thomas and Caleb Pratt in 1844, the Pratt truss successfully made the transition from wood designs to metal. The basic features are the diagonal web members which form a V-shape. The center section commonly has crossing diagonal members.

Charles Parker modified the Pratt truss to create a “camelback” truss having a top chord which does not stay parallel with the bottom chord. This creates a lighter structure without losing strength; there is less dead load at the ends and more strength concentrated in the center.

|

|

| http://pghbridges.com/basics.htm |

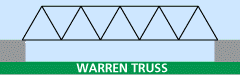

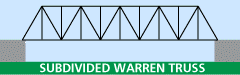

A Warren truss, patented by James Warren and Willoughby Monzani in 1848, contains many triangles formed by the web members which connect the top and bottom chords. These triangles may also be further subdivided. Warren truss may also be found in covered bridge designs.

|

|

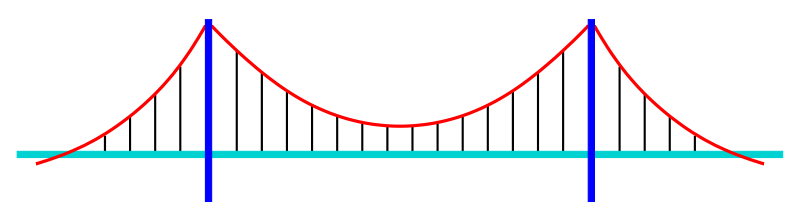

Suspension types

The longest bridges in the world are suspension bridges or their cousins, the cable-stayed bridge. The deck is hung from suspenders of wire rope, eye bars or other materials. Materials for the other parts also vary: piers may be steel or masonry; the deck may be made of girders or trussed.

How a suspension bridge works

| |

| http://www.aiacincinnati.org/community/abc/curriculum/fivebridgetypes.pdf |

The cables that go from the top of the towers down to the ground are the backstays. The backstays are connected to big rock or concrete piers buried in the ground. The backstays keep the towers from bending in.

Suspension bridges are very light. This allows them to span very long distances. The longest suspension bridge in the world is the Askashi Kaikyo Bridge in Japan. In addition to the long span, this bridge was designed to resist huge earthquakes and hurricane force winds.

Some bridges have in the past suffered from structural failure. This may be combination of poor design and severe weather conditions.

When it was opened in 1940, the Tacoma Narrows Bridge was the third longest suspension bridge in the world. It later became known as “Galloping Gertie”, due to the fact that it moved not only from side to side but up and down in the wind. Attempts were made to stabilize the structure with cables, but they were unsuccessful.

Eventually on November 7, 1940, only four months after it was built the bridge collapsed in a wind of 42 mph. The bridge was designed to withstand winds of up to 120 mph. Some experts have blamed the collapse of the bridge upon a phenomenon called resonance.

Today all new bridges prototypes have to be tested in a wind tunnel before being constructed. The Tacoma Narrows bridge was rebuilt in 1949.

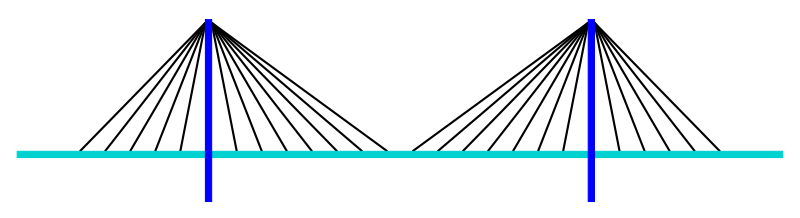

Cable-stayed type

A scientific understanding of the properties of modern materials and the availability of computer software have made it possible to construct new types of bridges. The newest type of bridge is the cable-stayed bridge. They have great popularity in recent years because of their great beauty and economy.

These modern bridges are designed using computer aided design (CAD). Bridge designers are now able to design a bridge on computer, simulate its use and correct any faults before building begins. Modern materials, especially special steels are used to construct this type of bridge. This means that bridges can be made from lighter, stronger materials and engineered precisely. Today materials are used efficiently. Older bridges (built in the 19th and early 20th century) such as suspension bridges were designed on paper and the design could not be simulated before being built. Consequently, designers ensured that early steel, stone, concrete bridges were constructed from more materials than were actually required – just in case the final bridge was too weak and collapsed.

Unlike suspension bridges, cable stayed bridges do not need anchor blocks. The cables are fixed to either side of each tower – this means that the weight of each side of the bridge counter balances the opposite side. The absence of anchor blocks substantially reduces the amount of materials needed and the cost of building the bridge. Also, the towers tend to be positioned down the centre of the roadway and half as many towers are needed compared to suspension bridges.

Two well known cable stay bridges can be found in France. The ‘Le Pont de Normandie’, can be found in Normandy, Northern France. This was once the longest cable stay bridge in the world. However, this engineering feat has been surpassed by the opening of the Millau Bridge in Southern France. This cable stay bridge is the highest bridge in the world, with its deck almost at the same height as the Eiffel Tower.

|

|

| Suspension type | Cable-stayed type |

Дата добавления: 2016-03-22; просмотров: 2035;