Comparison of Flexible and Rigid Pavement

| Flexible Pavements | Rigid Pavements |

| - Deformation in the subgrade is transferred to the upper layers | - Deformation in the subgrade is not transferred to subsequent layers |

| - Have low completion cost but repairing cost is high | - Have low repairing cost but completion cost is high |

| - Have low life span | - High life span |

| - Surfacing cannot be laid directly on the subgrade but a subbase is needed | - Surfacing can be directly laid on the subgrade |

| - Road can be used for traffic within 24 hours | - Road cannot be used until 14 days of curing |

| - Have low flexural strength | - Have high flexural strength |

| - Damaged by oils and certain chemicals | - No Damage by oils |

Asphalt

Asphalt (specifically, asphalt concrete) has been widely used since the 1920s. Most asphalt surfaces are laid on a gravel base, which is generally at least as thick as the asphalt layer, although some asphalt surfaces are laid directly on the native subgrade.

Asphalt (specifically, asphalt concrete) has been widely used since the 1920s. Most asphalt surfaces are laid on a gravel base, which is generally at least as thick as the asphalt layer, although some asphalt surfaces are laid directly on the native subgrade.

| http://rollacity.blogspot.ru/2012/09/city-of-rolla-weekend-e-updates-sept-21.html |

An asphalt concrete surface will generally be constructed for high volume primary highways having an average annual daily traffic load greater than 1200 vehicles per day. Advantages of asphalt roadways include relatively low noise, relatively low cost compared with other paving methods, and perceived ease of repair. Disadvantages include less durability than other paving methods, less tensile strength than concrete, the tendency to become slick and soft in hot weather and a certain amount of hydrocarbon pollution to soil and groundwater.

Concrete

| http://www.concretepavements.org/Membership/Newsletter/ISCP_enewsletter_Vol1_No2.htm |

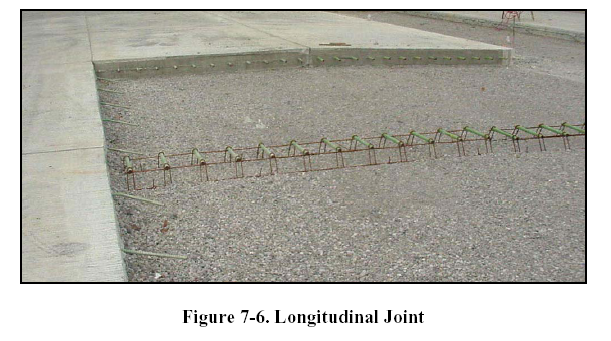

Concrete surfaces are divided into three common types: jointed plain (JPCP), jointed reinforced (JRCP) and continuously reinforced (CRCP). Each of the jointing system types is used to control crack development.

Concrete surfaces are divided into three common types: jointed plain (JPCP), jointed reinforced (JRCP) and continuously reinforced (CRCP). Each of the jointing system types is used to control crack development.

| http://dc261.4shared.com/doc/W3tVqUxD/preview.html |

Jointed reinforced concrete pavements control cracks by dividing the pavement up into individual slabs separated by contraction joints. However, these slabs are much longer than JPCP slabs, so JRCP uses reinforcing steel within each slab to control within-slab cracking. Today very few of agencies use this design, because it is not recommended as both of the other types offer better performance and are easier to repair.

Continuously reinforced concrete pavements use reinforcing steel rather than contraction joints for crack control. Cracks are held tightly together by the underlying reinforcing steel. A number of agencies have made decisions to use continuously reinforced designs in their heavy urban traffic corridors.

One of the major advantages of concrete pavements is that they are typically stronger and more durable than asphalt roadways. They can also provide a durable skid-resistant surface. A notable disadvantage is that it can typically have a higher initial cost, as well as can be more time consuming to construct. This cost can typically be offset through the long life cycle of the pavement.

Other pavements

Composite surface combines Portland cement concrete and asphalt. They are usually used to rehabilitate existing roadways rather than in new construction.

Composite surface combines Portland cement concrete and asphalt. They are usually used to rehabilitate existing roadways rather than in new construction.

| http://www.forconstructionpros.com/article/10616882/clearing-the-air-about-pneumatic-rollers |

The ease of application of BST is one reason for its popularity, but another is its flexibility, which is important when roadways are laid down over unstable terrain that thaws and softens in the spring.

The ease of application of BST is one reason for its popularity, but another is its flexibility, which is important when roadways are laid down over unstable terrain that thaws and softens in the spring.

| http://commons.wikimedia.org/wiki/File:Gravel_Road_Coober_Pedy.jpg |

Pavers generally have the form of pre-cast concrete blocks, are often used for aesthetic purposes. Pavers are rarely used in areas with high-speed vehicle traffic.

| en.wikipedia.org/wiki/Road_surface |

Brick, cobblestone, sett pavements were once common in urban areas throughout the world, but fell out of fashion in most countries, due to the high cost of labor required to lay and maintain them, and are typically only kept for historical or aesthetic reasons. In some countries, however, they are still common in local streets.

Brick, cobblestone, sett pavements were once common in urban areas throughout the world, but fell out of fashion in most countries, due to the high cost of labor required to lay and maintain them, and are typically only kept for historical or aesthetic reasons. In some countries, however, they are still common in local streets.

Step I: Planning

A road project begins with evaluating the transportation system, taking into account statewide priorities, including strategic plans for the state’s transportation system. Department of Transportation collects  and maintains information about our roads, including road and bridge conditions, traffic volumes, crash statistics.

and maintains information about our roads, including road and bridge conditions, traffic volumes, crash statistics.

Using this data, transportation planners, engineers, environmentalists, landscape architects, soil scientists and others identify trends that determine what and how to build.

| http://www.michigan.gov/mdot/0,1607,7-151-9615-129011--,00.html |

A survey of the area is step two. Recently, Global Positioning Systems, laser surveys, and other technology have sped up the process and improved accuracy. Many factors influence designs, including location, terrain and soil properties, drainage capabilities, traffic volume, the ratio of cars to trucks and buses, possible future development in the area, effects on the environment or nearby residents.

Дата добавления: 2016-03-22; просмотров: 3527;