HEAT EXCHANGERS

As stated above all power and refrigeration plants contain equipment which has as its major function the transfer of heat from one fluid to another. This equipment includes boilers, superheaters, economizers, heaters, coolers, condensers, and evaporators and is called a heat exchanger. The same laws of heat transfer, fluid flow, and economics apply to all heat exchangers. Heat exchangers differ in design characteristics only because of the different functions which they perform and conditions under which they operate.

As stated above all power and refrigeration plants contain equipment which has as its major function the transfer of heat from one fluid to another. This equipment includes boilers, superheaters, economizers, heaters, coolers, condensers, and evaporators and is called a heat exchanger. The same laws of heat transfer, fluid flow, and economics apply to all heat exchangers. Heat exchangers differ in design characteristics only because of the different functions which they perform and conditions under which they operate.

Two heat exchangers commonly found in stationary power plants are the steam condenser and feed-water heater. They are distinct and separate pieces of equipment, and they differ in their relative positions and primary functions in the cycle. The purpose of the feed-water heater is to increase the overall efficiency of the cycle. This is accomplished by heating the boiler water before it enters the boiler with either waste steam or steam extracted from the turbine. With the feedwater entering the boiler at high temperatures, the boiler is relieved of a part of its load and temperature stresses within the boiler are reduced. Feed-water heaters are designed as direct-contact heaters or surface heaters.

The direct-contact heater is often called an open heater, although it may operate at pressures above atmospheric pressure. A typical direct-contact heater consists mainly of an outer shell in which are placed trays or pans. Water enters at the top of the shell. It feeds by gravity over rows of staggered trays which break up the solid stream of water. Steam entering near the center of the shell intimately mingles with the water and condenses.

In condensing, the steam gives up heat to the water. The heated water and condensate mixture is collected at the bottom of the shell and is removed by a boiler feed pump. A float control operating the inlet water valve maintains a constant level in the feed-water tank. A vent at the top removes the excess steam and the noncondensable gases. In the larger heaters where the vented steam is appreciable, a vent condenser may be employed. Water, before it enters the tray section of the feed-water heater, is passed through coils in the vent condenser. Heat is transferred from the vented steam to the water as the steam is condensed. The condensate from the vent condenser is returned to the heater. Noncondensable gases are expelled to the atmosphere.

Because of the stress limitations of the heater shell, the steam pressure is limited to a few pounds per square inch above atmospheric pressure although pressures to 70 psia have been used. Consequently, the feedwater is rarely heated above 220° F. If direct-contact heaters are used in series, a feed-water pump must be installed ahead of each heater. The advantages of the direct-contact feed-water heater are: 1) complete conversion of the steam to water is accomplished; 2) noncondensable corrosive gases are removed from the feedwater; 3) the removal of impurities in the water is possible; 4) the water is brought to the temperature of the steam; 5) the heater acts as a small reservoir.

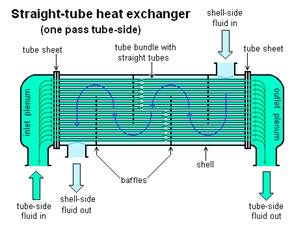

Closed heaters or surface-type feed-water heaters are of the shell and tube design. Generally, the water is introduced to the heater through tubes around which the steam circulates. Closed heaters may be classified as single- or multipass and straight tube or bent tube. In a single-pass heater the water flows in only one direction. In a multipass heater the water reverses direction as many times as there are passes. In a two-pass straight tube type of closed feed-water heater water enters at the bottom of one end of the heater and flows through the lower bank of tubes to the opposite end where its direction is reversed. The water returns through the upper bank of tubes to the outlet at the top. Steam enters the shell at the top and flows toward each end, and condensate leaves the shell at the bottom.

A floating head is provided to permit the tubes to expand. Vents at the top are provided to remove gases trapped in the shell. This heater is designed for a water pressure of 1100 psi. Closed heaters placed in series require only one feed-water pump unless the pressure drop through the healers is high. If bent tubes are used in place of the straight tubes, no floating head is necessary. However, the bent tubes may be difficult to clean.

In closed heaters the feedwater can never be heated to the temperature of the steam, but generally the terminal temperature difference at the outlet is not greater than 15° F.

To maintain a high overall heat transfer for the heater the water velocity should be high, but pumping costs will limit the velocity. A balance between pumping costs and the amount of heat transferred will result in water velocities of 3 to 8 fps. Generally, the heaters are rated in terms of the square feet of heat-transfer surface and of the quantity of heat transferred.

Дата добавления: 2015-06-17; просмотров: 2054;