PART 1.DRILLING AND REAMING

TEXT A . Introduction

Drilling is a process of producing round holes in a solid material or enlarging existing holes with the use of multi- tooth cutting tools called drills or drill bits. Various cutting tools are available for drilling, but the most common is the twist drill.

Reaming is a process of improving the quality of already drilled holes by means of cutting tools called reamers. Drilling and reaming are performed on a drilling press, although other machine tools can also perform this operation, for instance lathes, milling machines, machining centers.

In drilling and reaming, the primary motion is the rotation of the cutting tool held in the spindle. Drills and reamers execute also the secondary feed motion. Some finishing reaming operationsare manual.

Drilling and reaming operations

Several operation are related to drilling, most of them illustrated in the figure:

Several operation are related to drilling, most of them illustrated in the figure:

lling is used to drill a round blind or through hole in a solid material. If the hole is larger than ~30 mm, its a good idea to drill a smaller pilot hole before core drilling the final one. For holes larger than ~50 mm, three-step drilling is recomended;

v Core drilling is used to increase the diameter of an existing hole;

v Step drilling is used to drill a stepped (multi-diameter) hole in a solid material;

v Counterboring provides a stepped hole again but with flat and perpendicular relative to hole axis face. The hole is used to seat internal hexagonal bolt heads;

v Countersinking is similar to counterboring, except that the step is conical for flat head screws:

v Reaming provides a better tolerance and surface finish to an initially drilled hole. Reaming slightly increases the hole diameter. The tool is called reamer;

v Center drilling is used to drill a starting hole to precisely define the location for subsequent drilling. The tool is called center drill. A center drill has a thick shaft and very short flutes. It is therefore very stiff and will not walk as the hole is getting started;

v Gun drilling is a specific operation to drill holes with very large length-to-diameter ratio up to L/D ~300. There are several modifications of this operation but in all cases cutting fluid is delivered directly to the cutting zone internally through the drill to cool and lubricate the cutting edges, and to remove the chips.

Drilling machines

Drill press

Although a hand drill is commonly used for drilling of small holes, a drill press is preferable when the location and orientation of the hole must be controlled accurately. A drill press is composed of a base that supports a column, the column in turn supports a table. Work can be supported on the table with a vise or hold down clamps, or the table can be swivelled out of the way to allow tall work to be supported directly on the base. Height of the table can be adjusted with a table lift crank than locked in place with a table lock. The column also supports a power head containing a motor. The motor turns the spindle at a speed controlled by a variable speed control dial. The spindle holds a drill chuck to hold the cutting tools (drill bits, center drills, reamers, etc.).The machine tool described is a typical upright drill press. The smaller modifications, mounted on a table rather than the floor are known as bench drills.

Although a hand drill is commonly used for drilling of small holes, a drill press is preferable when the location and orientation of the hole must be controlled accurately. A drill press is composed of a base that supports a column, the column in turn supports a table. Work can be supported on the table with a vise or hold down clamps, or the table can be swivelled out of the way to allow tall work to be supported directly on the base. Height of the table can be adjusted with a table lift crank than locked in place with a table lock. The column also supports a power head containing a motor. The motor turns the spindle at a speed controlled by a variable speed control dial. The spindle holds a drill chuck to hold the cutting tools (drill bits, center drills, reamers, etc.).The machine tool described is a typical upright drill press. The smaller modifications, mounted on a table rather than the floor are known as bench drills.

Radial drill

This is the largest drill press designed to drill up to 100-mm diameter holes in large workparts. It has a radial arm along which the drilling head can be moved and clamped.

This is the largest drill press designed to drill up to 100-mm diameter holes in large workparts. It has a radial arm along which the drilling head can be moved and clamped.

Other drilling machines

The gang drill is a drill press consisting of a series of drill presses connected together in an in-line arrangement so that a series of drilling operations can be done in sequence.

In the multiple-spindle drill, several drill spindles are connected together to drill multiple holes simultaneously into the workpart.

Numerical control drill presses are available to control the positioning of the holes in the workparts. These drill presses are often equipped with turrets to hold multiple tools that can be indexed under control of the NC program. The term CNC turret drill is used for these machine tools.

Workholding equpment

Workholding on a drill press is accomplished by clamping the part in a vise, fixture, or jig.

A vise is a general-purpose workholding device possessing two jaws that grasp the work in position.

A fixture is a workholding device that is usually custom designed for the particular workpart. The fixture can be designed to achieve higher accuracy in positioning the part relative to the machining operation, faster production rates, and greater operator convenience in use.

A jig is a workholding device that is also specially designed for the workpart. The distinguishing feature between a jig and a fixture is that the jig provides a means of guiding the tool during the drilling operation. A fixture does not provide this tool guidance feature. A jig used for drilling is called a drill jig.

Drills and reamers

Twist drill

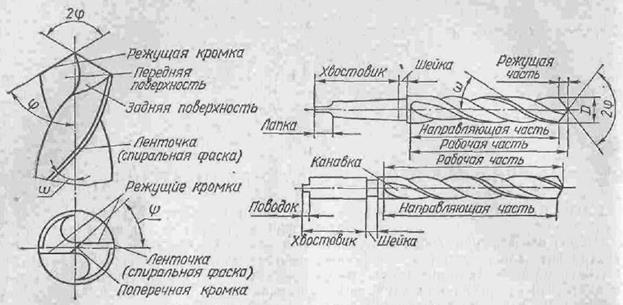

The twist drill does most of the cutting with the tip of the bit. It has two flutes to carry the chips up from the cutting edges to the top of the hole where they are cast off. The standard drill geometry is shown in the figure:

The typical helix angle of a general purpose twist drill is 18~30o while the point angle (which equals two times the major cutting edge angle) for the same drill is 118o.

Some standard drill types are,

v straight shank: this type has a cylindrical shank and is held in a chuck;

v taper shank: is type is held directly in the drilling machine spindle.

Drills are normally made of HSS but carbide-tipped drills, and drills with mechanically attached carbide inserts are commonly used in many operations, especially on CNC drilling machines:

Drills are normally made of HSS but carbide-tipped drills, and drills with mechanically attached carbide inserts are commonly used in many operations, especially on CNC drilling machines:

Reamers

The reamer has similar geometry. The difference in geometry between a reamer and a twist drill are:

v The reamer contains four to eight straight or helical flutes, respectively cutting edges.

v The tip is very short and does not contain any cutting edges.

EXERCISES:

I. Find in the texts the following topical words and phrases, explain what they mean, and add them to your Active Vocabulary:

Twist drill, reaming, counterboring, lubricate, clamps, multiple spindle drill, straight shank, taper shank.

II. Write out from the texts the sentences or the parts of the sentences which contain the following words and expressions and translate them into Russian:

define the location, be swiveled, in-line arrangement, turrets, vise, fixture,jig.

III. Answer the following questions:

1. What does drilling mean?

2. What kind of drilling do you know?

3. What is the difference between drilling and reaming?

4. What machine can be used for drilling the holes of 90 mm in diameter?

5. How can a drill be fixed to the drilling machine?

TRANSLATION

EXERCISES:

I. Before translating the text, find in it the sentences in which you would be able to use the following topical words and expressions:

Taper shank, flute, main cutting edge, chisel, multiple-spindle drill, radial drill, gang drill.

II. Read the text again, find in it the information about the following questions, and answer them using the topical words and phrases:

1. What kind of holes can be produced with the drill press?

2. What types of drill press are used for drilling?

3. What kind of tool is used to improve the hole quality?

4. Name the parts of the drill.

5. How can the accuracy of a hole be obtained?

TEXT B

Большинство деталей машин имеют круглые отверстия. Отверстия бывают сквозные, глухие, цилиндрические, конические и резьбовые. Особое место занимают глубокие отверстия, в которых длина в 10 раз превышает их диаметр.

Станки сверлильной группы предназначены для обработки всех типов круглых отверстий и в редких случаях – многогранных отверстий.

Имеется много типов сверлильных станков.

Наибольшее распространение имеют одношпиндельные вертикальносверлильные станки, радиальносверлильные станки и многошпиндельные станки.

Особое место в группе сверлильных станков занимают расточные станки.

Основным инструментом, позволяющим путем механической обработки получить глухие и сквозные отверстия в сплошном материале, является сверло. Сверла бывают разных типов: спиральные, перовые и др.

Элементы сверла. Основными элементами сверла являются: головка, рабочая часть, хвостовик и лапка.

Основные виды работ.

Для получения отверстий в сплошном материале применяют операцию сверления. Для обработки отверстий диаметром до 50 – 80 мм используют спиральные сверла, а для изготовления отверстий больших размеров применяют пустотелые кольцевые сверла. Точные и чистые отверстия обрабатываю последовательно тремя инструментами: сверлом, зенкером и разверткой.

Обработка отверстий под головки винтов и шурупов производится зенкерами и зенковками.

Торцы отверстий обрабатываются цековками.

Операция растачивания отверстий производится только на расточных станках. Сверлильные станки для этой работы не приспособлены.

PART 2: MILLING

TEXT A. MILLING

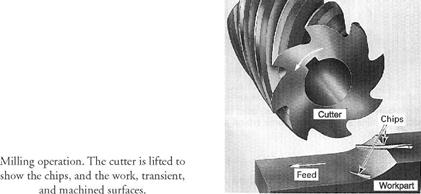

Milling is a process of producing flat and complex shapes with the use of multi-tooth cutting tool, which is called a milling cutter and the cutting edges are called teeth. The axis of rotation of the cutting tool is perpendicular to the direction of feed, either parallel or perpendicular to the machined surface. The machine tool that traditionally performs this operation is a milling machine.

Milling is an interrupted cutting operation: the teeth of the milling cutter enter and exit the work during each revolution. This interrupted cutting action subjects the teeth to a cycle of impact force and thermal shock on every rotation. The tool material and cutter geometry must be designed to withstand these conditions. Cutting fluids are essential for most milling operations.

|

Дата добавления: 2016-04-22; просмотров: 1408;