TYPES OF ECONOMIZERS

Economizers for power station service are of two classes, steaming and non-steaming. Both have been used and choice will depend largely on the feed-water temperature and the boiler pressure. If the turbines are bled to such an extent that the final feed-water temperature is raised to within a few degrees of the saturation, temperature, it is apparent that no further heat can be added in an economizer unless a steaming economizer is used. The function of this economizer is to supply the boiler with a percentage of wet steam along with the feed water and a number of pipe connections are taken from the economizer outlet to the boiler drum. A saving may be effected in both capital cost of the boiler and building with large steaming economizers. The construction and location of both classes of economizers are similar, the chief difference being that only one outlet connection is required on the non-steaming economizer. With a steaming economizer, boiler baffles are eliminated resulting in a reduction of draught loss and fan power. During intermittent feeding with cold feed, temperature changes occur at the economizer inlet joints which may result in joint failure.

Economizers for power station service are of two classes, steaming and non-steaming. Both have been used and choice will depend largely on the feed-water temperature and the boiler pressure. If the turbines are bled to such an extent that the final feed-water temperature is raised to within a few degrees of the saturation, temperature, it is apparent that no further heat can be added in an economizer unless a steaming economizer is used. The function of this economizer is to supply the boiler with a percentage of wet steam along with the feed water and a number of pipe connections are taken from the economizer outlet to the boiler drum. A saving may be effected in both capital cost of the boiler and building with large steaming economizers. The construction and location of both classes of economizers are similar, the chief difference being that only one outlet connection is required on the non-steaming economizer. With a steaming economizer, boiler baffles are eliminated resulting in a reduction of draught loss and fan power. During intermittent feeding with cold feed, temperature changes occur at the economizer inlet joints which may result in joint failure.

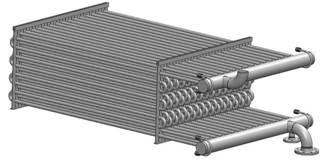

Modern economizers are constructed with steel tubes, which are necessary for high pressures. In order to conserve space, the tube surface is usually made in one continuous loop with connection pieces between the ends of the horizontal tube sections. Early designs used cast-iron tubes, the tubes being screwed into the headers. In modern economizers the tubes made of steel are usually 2,5 or 3 in. in diameter and are rolled into one or two headers only. Feed water is fed to one end of the lower header and distributed to each of the parallel-tube circuits. The last tube element may be rolled directly into the drum, and there is a growing tendency in design to eliminate all bolted return bends, the tube being in one continuous loop.

In constructions of continuous and of return bends, the bends are usually made of forged steel and are carefully machined to receive the tube ends. Gaskets which are necessary where the tube ends bear against the female joint of the return bend, may be of some soft material such as granite. In order to keep the gas passage restricted to the straight section of the tubes and to give support to the tubes, it is customary to use tube sheets of cast iron. The outside casing is then made of removable steel-plate panels which are insulated, it thus being necessary to remove the whole side to obtain access to a certain tube. When there is a reversal of gas passage, soot hoppers are commonly placed below the economizer to collect any soot carry-over from the boiler, the soot being piped to the ashpit.

Economizers when used in combination with air heaters are practically always set nearest to the boiler flue-gas exit. Although most economizers do not heat the feedwater to a point where it vaporizes, a number of steaming economizers have been built and operate successfully. In these, the individual parallel-tube elements run separately to the top rear drum of the boiler and are rolled directly into the drum. Relief connections between the drum and the economizer are not provided. In addition to a gain in over-all boiler efficiency of 10 to 12 per cent, depending upon the drop in gas temperature, an economizer will provide nearly as much additional generating capacity. Maintenance, it is claimed, will amount to as little as 0.5 to 1 per cent per year.

Дата добавления: 2015-06-17; просмотров: 2841;